3D Modeling and CAD

Designing 3D Objects

While learning about 3D Printing, I was most intrigued by the possibility to modify and repair existing products. While there is an amazing community with lots of good and free models around, naturally I came to a point where I did not find what I was looking for readily designed. I realized this is an essential skill for effectively operating not just 3D Printers, but any productive machine really.

Since youtube was the place I was learning all about 3D Printing, and all the people that I looked up to there were using Fusion 360 as their CAD Program that’s what I got into. In hindsight, that was a pretty good choice and I am in love with the abilities parametric design gives me. Below you will find some of my designs. The process is something that I enjoy a lot and wish to dive into deeper.

By trial and error, I already learned a lot about designing specifically for 3D Printing, but I often feel that there are many aesthetic considerations in design that I am not familiar with. I want to broaden my general ability to design physical objects, which is something I hope to gain during my master’s.

Check out more of my finished designs in the Prusaprinters (now Printables) Community

3D Scanning and Photogrammetry

Besides coming up with new objects, incorporating the real world is also an interest of mine.

Interaction with real objects and environments

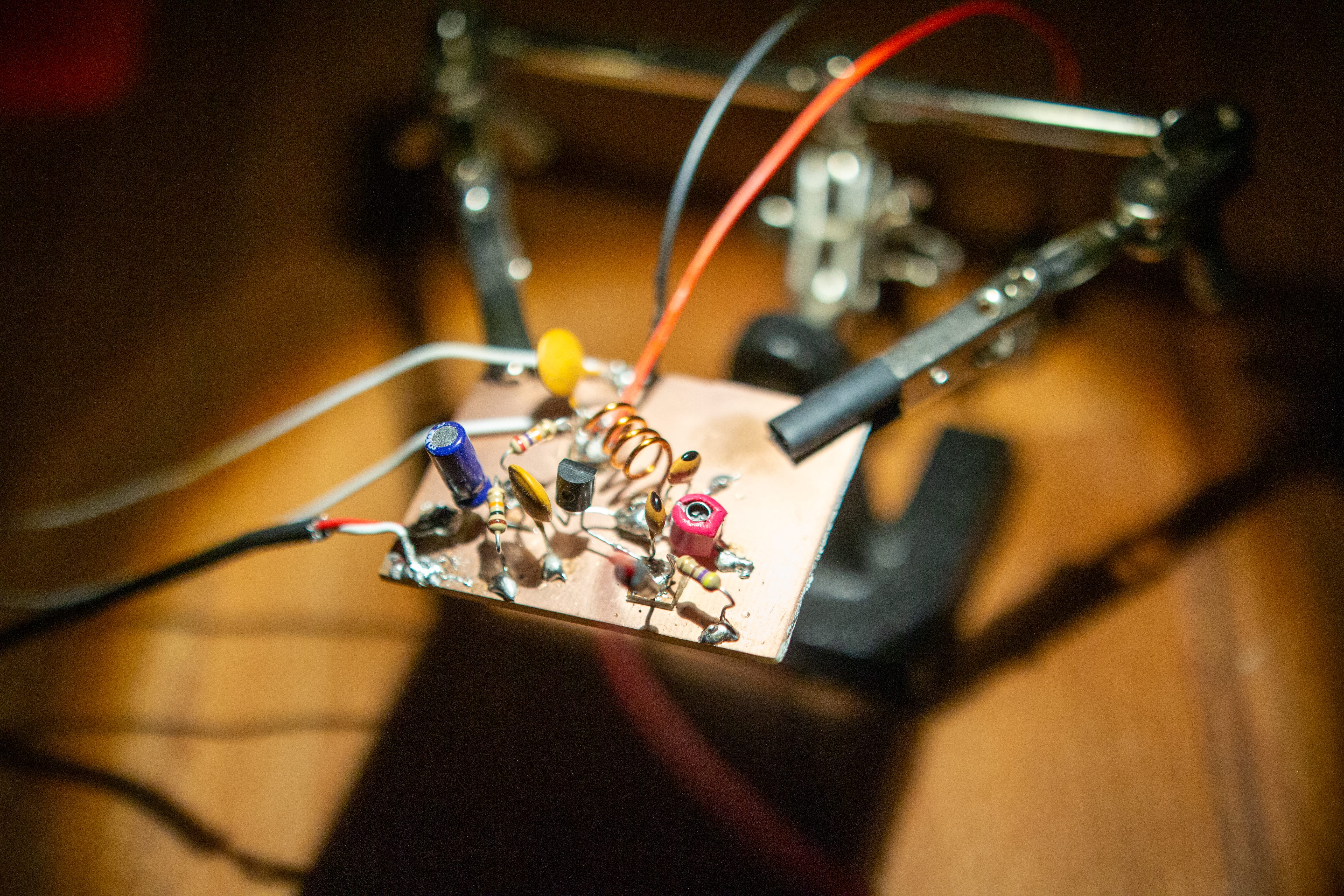

In the last few years I have played around with a few smartphone cameras and was always quite sad, that my scans were never quite accurate enough to do cool stuff with them. I could not really afford real 3D scanner and had already started cobbling together a raspberry Pi camera with a cheap TOF sensor, which is a simple, but not quite as good replacement for a laser or a lidar sensor, but then Apple came out with the first phones with accessible Lidar sensor. Recently, through work at the university I got access to a device with a lidar sensor and started having fun with it. See some examples here:

This last one was scanned with just my smartphone camera. You can see that the quality is notably worse, but considering is was created with just a single, run-of-the-mill smartphone sensor, I think it is still pretty impressive and will certainly do something towards democratizing such technologies and abilities.

Perspective

What this section is supposed to deliver is the message that I am currently not where I want to be navigating the vast possibilities of CAD. I feel confident enough to approach small repairs around the flat with a new perspective, but I still lack technical expertise when approaching a collection composite parts, having to function together. I still have lots of projects halfdone or half-thought and one major reason is that there is no real critical exchange within my field of study.

I want more than designing figurines or wearables. I want to incorporate 3D printing as a method to extend the abilities of other tools, have mechanical and electrical purposes, be foodsafe and engaging. I fell in love with the idea of designing a toy system, inspired by Makeways on Kickstarter, I have already started adding my own parts to their set.

I dream of my very own 3D printed coffeecup, one that is both foodsafe and dishwasher-surviving. For that, I would have to do quite a bit of material research, but that just makes the idea so much more appealing. I would love finding a material composition incorporating waste to stop relying on plastics, or at least on fossile plastics. Once in Berlin, I would want to talk to the people at Kaffeform producing largely compostable Coffee Cups incorporating a significant amount of old ground espresso, albeit using injection molding for their process. The industry selling composite filaments is much more conservative with the percentage of non-plastic additives, because with a nozzle extrusion process there is much more to go wrong. Still, I would love to explore that avenue further and think there is a lot to be gained from looking at pellet printers.

I also credit huge parts of my exploration process into local recycling to the awesome people at Precious Plastic, who I will join over the summer to learn more about their system.

I find it hard to write anything about CAD without connecting it directly to a manufacturing process. And I believe that’s a good thing. Always tying a design process to its realization, grounds the process and attaches to it some immediacy.

For me to become more confident in this process, I am still missing more expertise in organic shapes, so I would be happy to dig more into Blender, an awesome tool that in my mind is far too powerful to dive into it with just youtube lessons.

Software that I have used and like

AliceVision Meshroom Scaniverse My Sketchfab Profile 3D Live Scanner for Android