Iron Smelting

Impressions from the International Smelting Days 2021

The concept

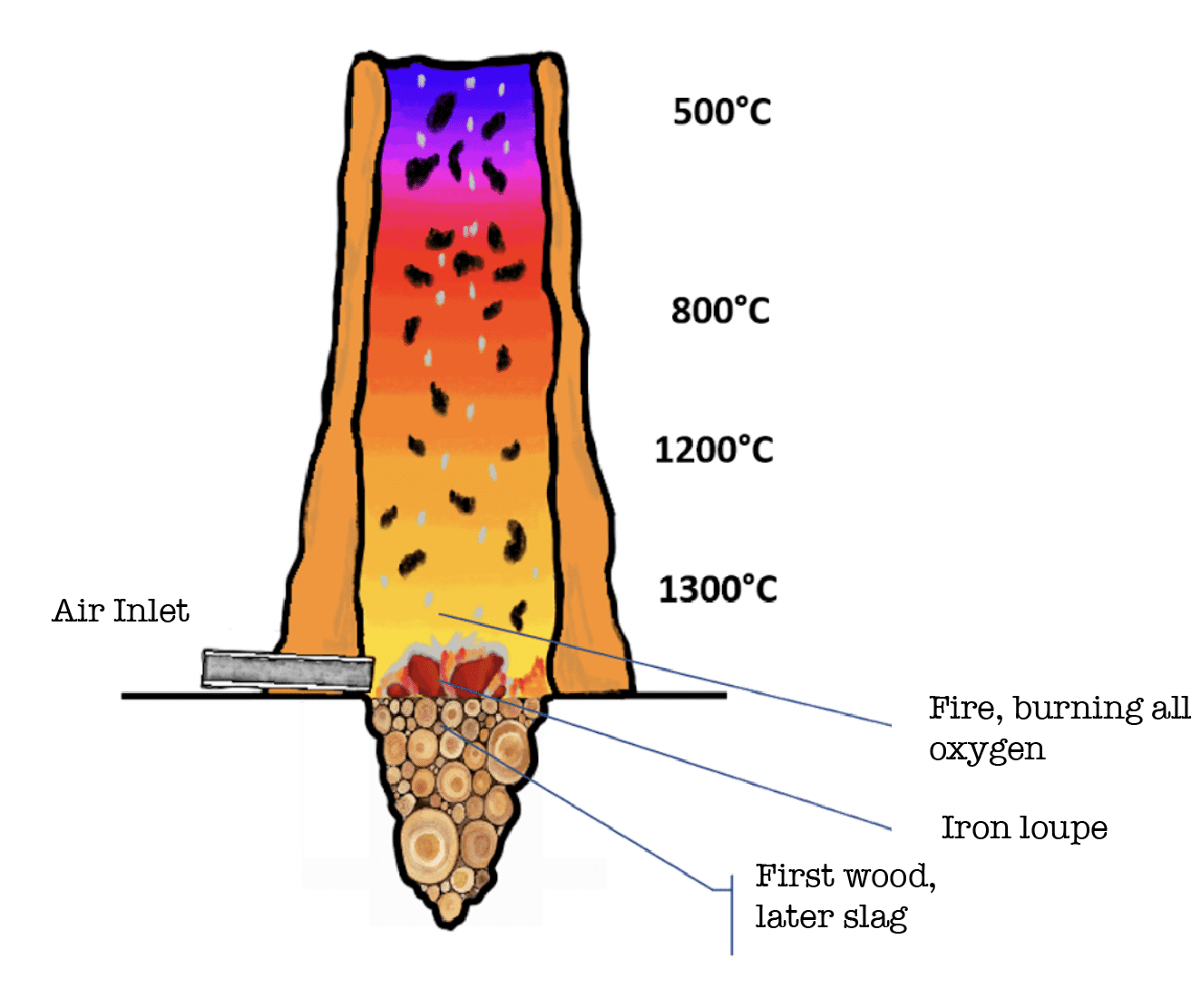

Since I was a small child I regularly took part in the yearly international congress called Iron Smelting Days (ISD). This is a congress of transdisciplinary people from all over Europe, including historians, archeologists, blacksmiths, steel producers, and many invested hobbyists. The proclaimed goal of these events is to understand the ancient production of iron as it happened throughout the iron age and also much after. A bloomery furnace was used to create iron. Making iron requires iron ore and heat under the exclusion of oxygen. It is a highly fragile process that takes an incredible amount of work. The designs and methods vary a lot and were very adapted to the region and local conditions, unlike the much later, more industrialized process using blast furnaces.

To this day it is quite unclear how prehistoric people managed to get the amount and quality of iron we know they had. The furnaces that were built were often clay structures and are not preserved. Archeologists often find the leftover burned ore and minerals, giving us some indication of the structure and composition of the ancient furnaces. The group around the ISD takes up a practical archeological approach and we try to recreate the ancient methods with the added capability of maybe sticking temperature probes or electric blowers. Each year we meet up in a different European city and try to adapt to the local conditions, often with local ore and local coal. It is a place where different areas of expertise come together to educate each other while sitting together through the intense day- and night shifts to feed the furnaces. Since being a kid, I started building my own furnaces and read up on the process so I could participate. Technology gets a different tint when one is involved in such a process: Even the lights we put up to work through the evening are technically cheating. We use thermometers, meticulously weigh and track the inbound coal and ore, and have many modern amenities around. Yet - with our much more advanced technology, our results are often inferior in quantity and quality in comparison with historical findings. Without modern scales, iron-age people were more accurate and consistent than we are.

After some uncertainty about whether it would take place in 2021 again after it was canceled in 2020, a small group met up in Ulft, Netherlands. This year in Ulft, another group made local coal, so that the entire process was even lengthier, and visitors came from all over to learn about making iron the pre-historic way.

Below I captured most of the process in some time-lapses.

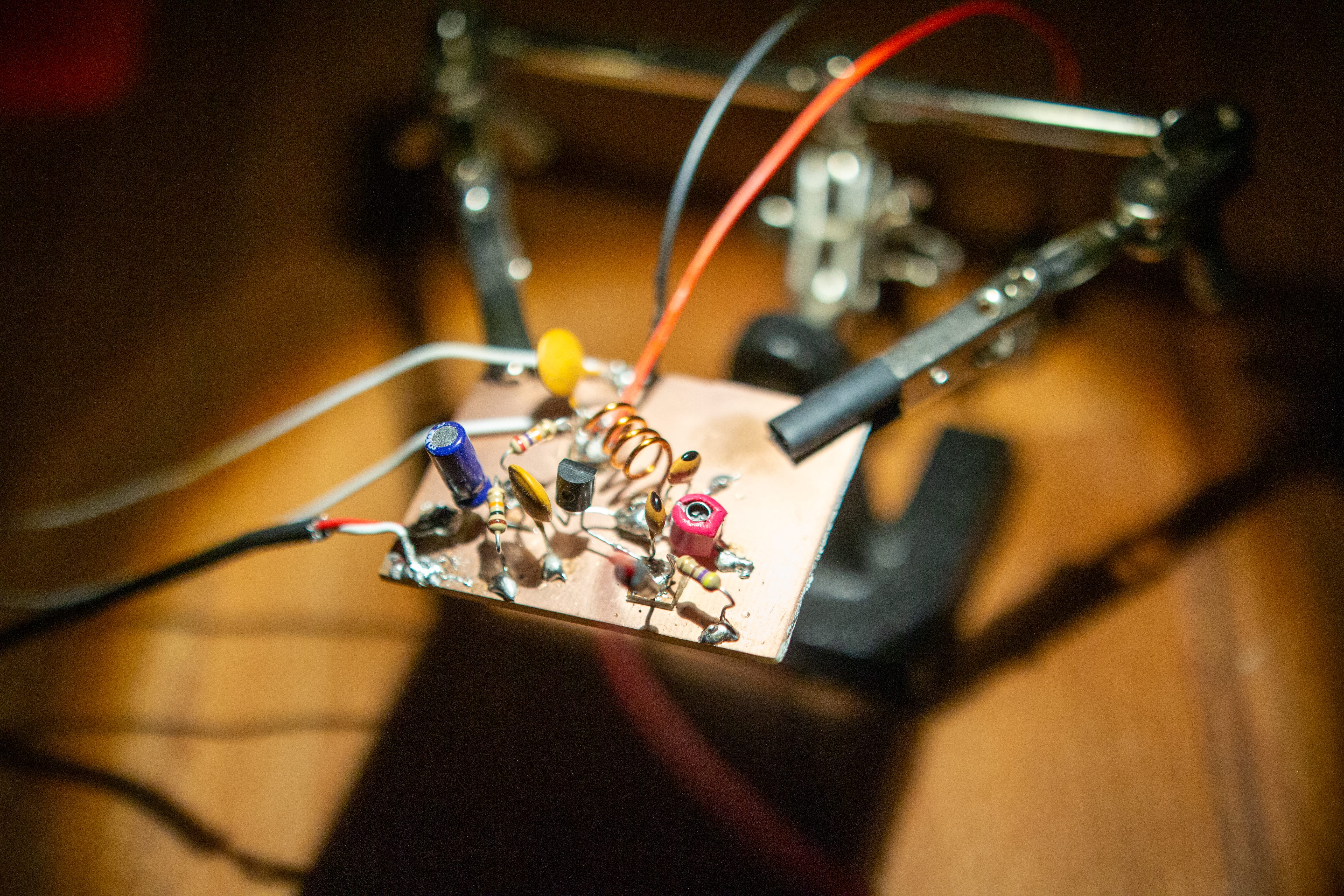

The Process

Here you can see a timelapse of me building a version of an Iron Furnace

As you can see, we are using some quite modern materials, such as bricks, this is due to the time constraints of the ISD. Making an oven completely from scratch is a much more lengthy process requiring drying periods in between building.

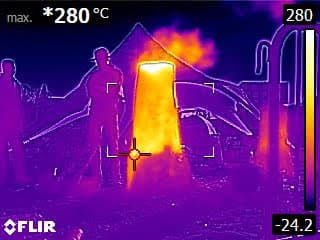

After, the furnace is dried and heated up

Over the course of the process, more than 100 kgs of coal and around 20 kgs of ore are used to create a final piece of iron of 200 - 500g, just enough for a single knife.

With all the modern amenities and conveniences available to us, a single run still takes more than 3 people working over 72 hours, not accounting for the coal-making or mining and relocating the iron ore.

For me, it is very hard to define what technology encompasses. It certainly goes beyond the typically associated imagery of computing and industrial progress. It is a mode of encompassing the world and adopting other technologies, be it by time or by region makes me feel how diffused the phenomenon of technology is into my world.