3D printing

3D Printing

3D Printing is more than just a hobby for me

In it, I see societal changes, the democratization of production, and creative possibilities. Plastic does not have to be one of our greatest environmental problems if we just choose to change our perspective and behavior toward it. Plastic Injection molding was one major driving force for the capitalist setting we are in now. 3D Printing can be utilized to counteract the production of scale. Today, the buzzword 3D Printing is already associated with problematic societal practices, it is related to “automatization” and “on-demand economy”. The technology has many aspects to be considered and evaluated and as a technology, many awesome things happen through it and on the same page it fuels developments I would consider problematic. Due to a history of patents influencing the development of the technology, and avid adoption of companies hoping to optimize production processes and margins, but also a very active hobbyist community, all sorts of projects are realized. While certainly societally explosive, there is still a lot going for 3D Printing.

3D Printing means local and custom production. While I do not buy the whole “every household is going to have a machine that prints what they need right now at the press of a button”, I do see vast potential in 3D Printing. That’s why I want to build my future on it. I want to design things and make them become reality. A 3D Printer lets me control that process from start to finish. Being able to design a thing in CAD is not enough here, I also need to be able to fully understand and control the machine that makes my thing.

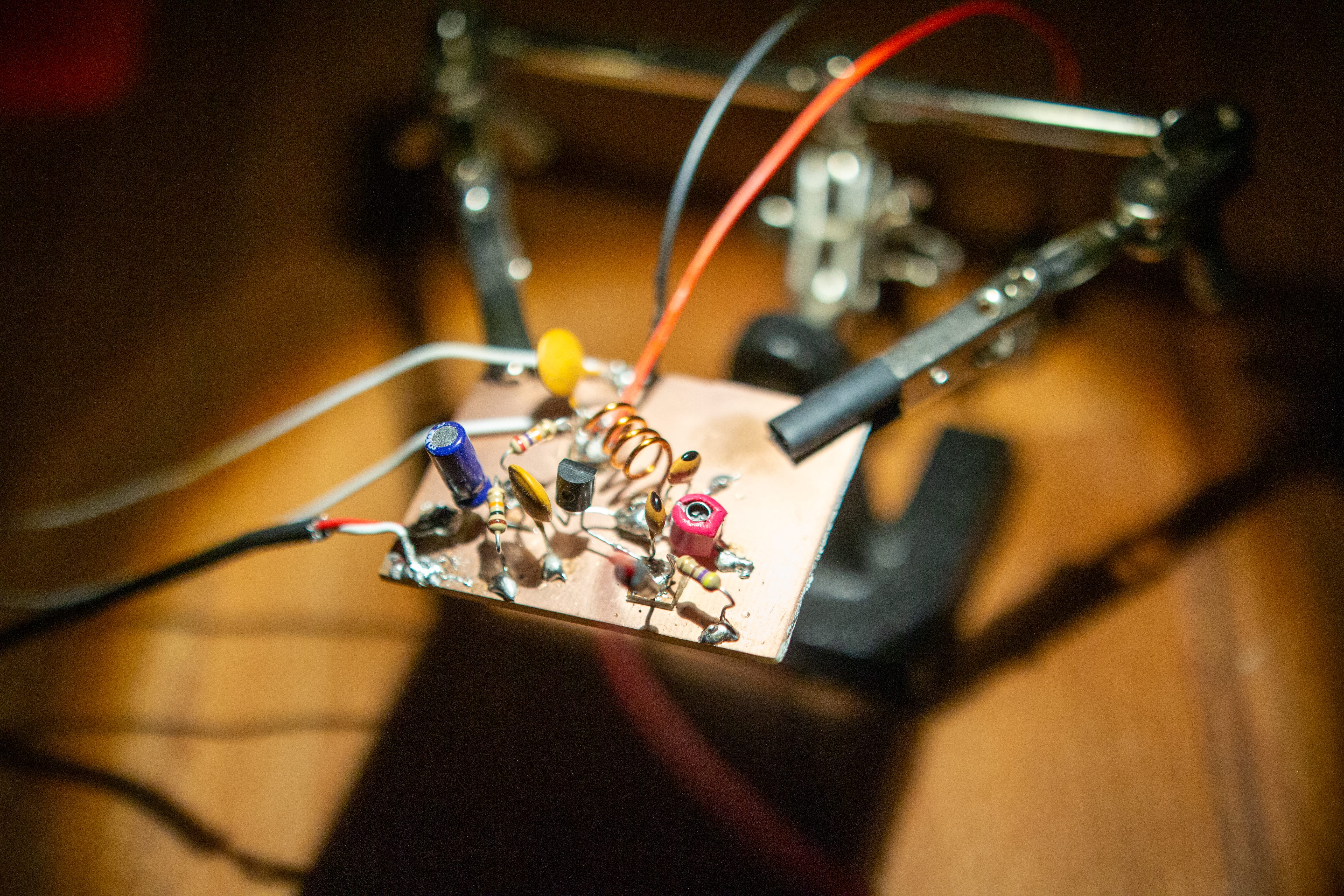

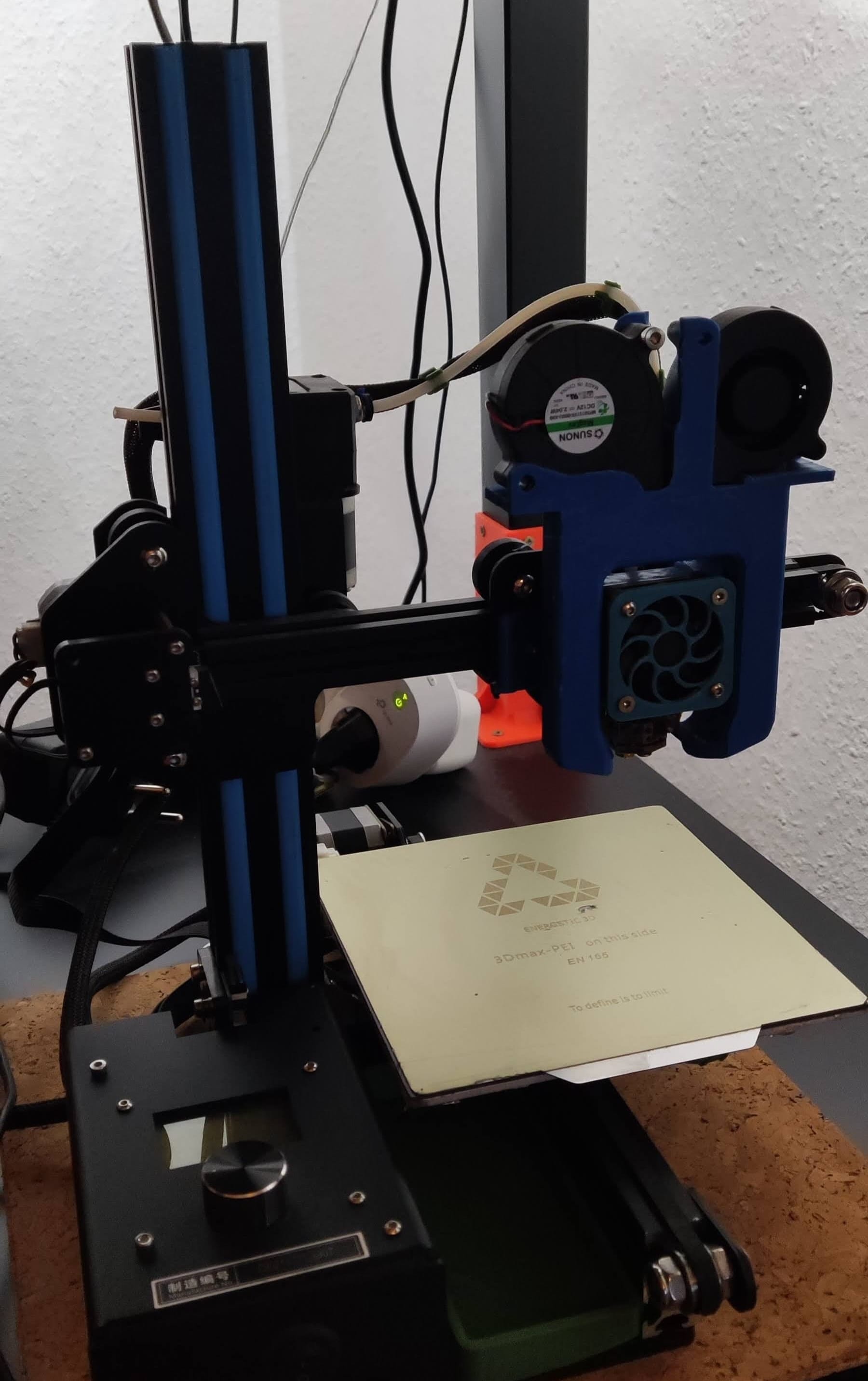

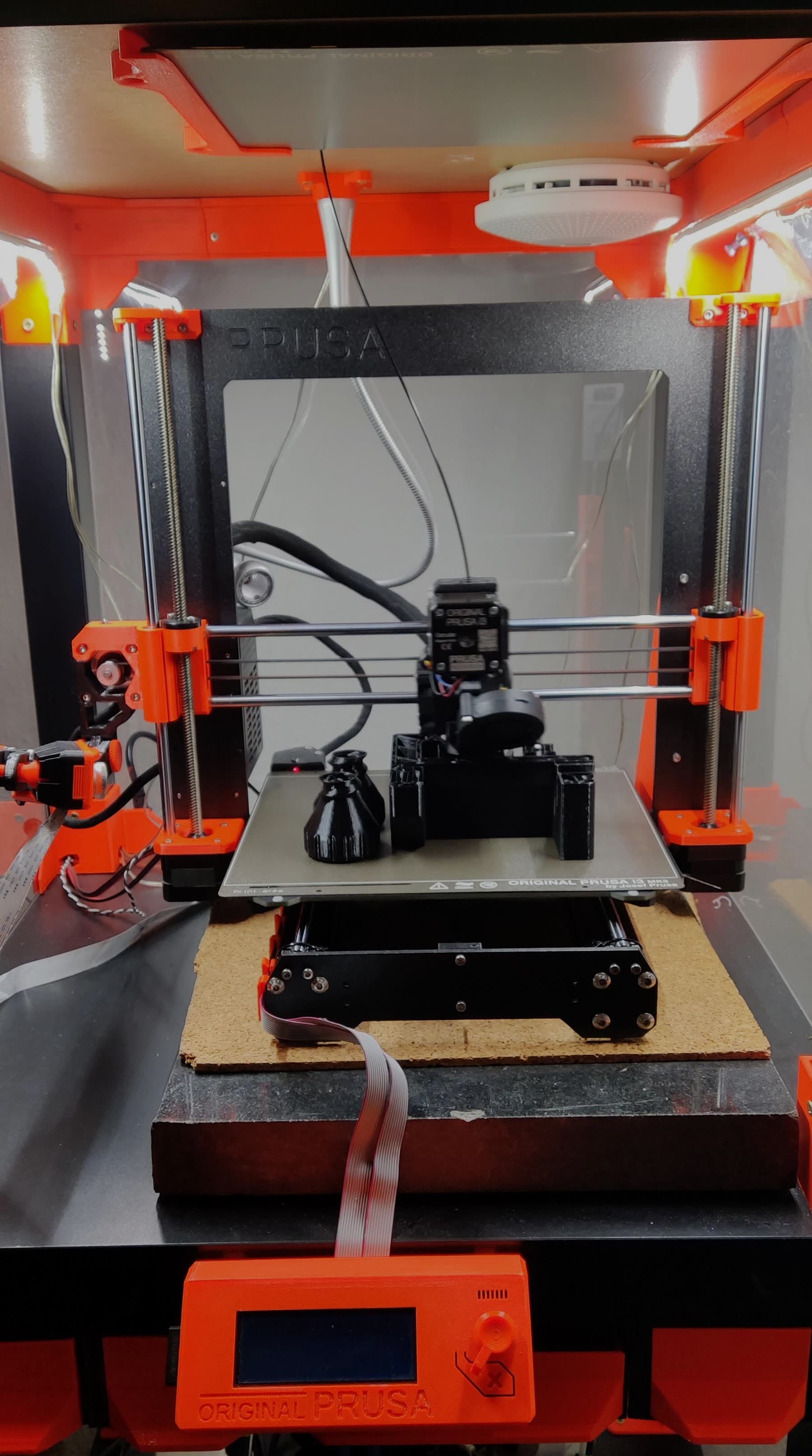

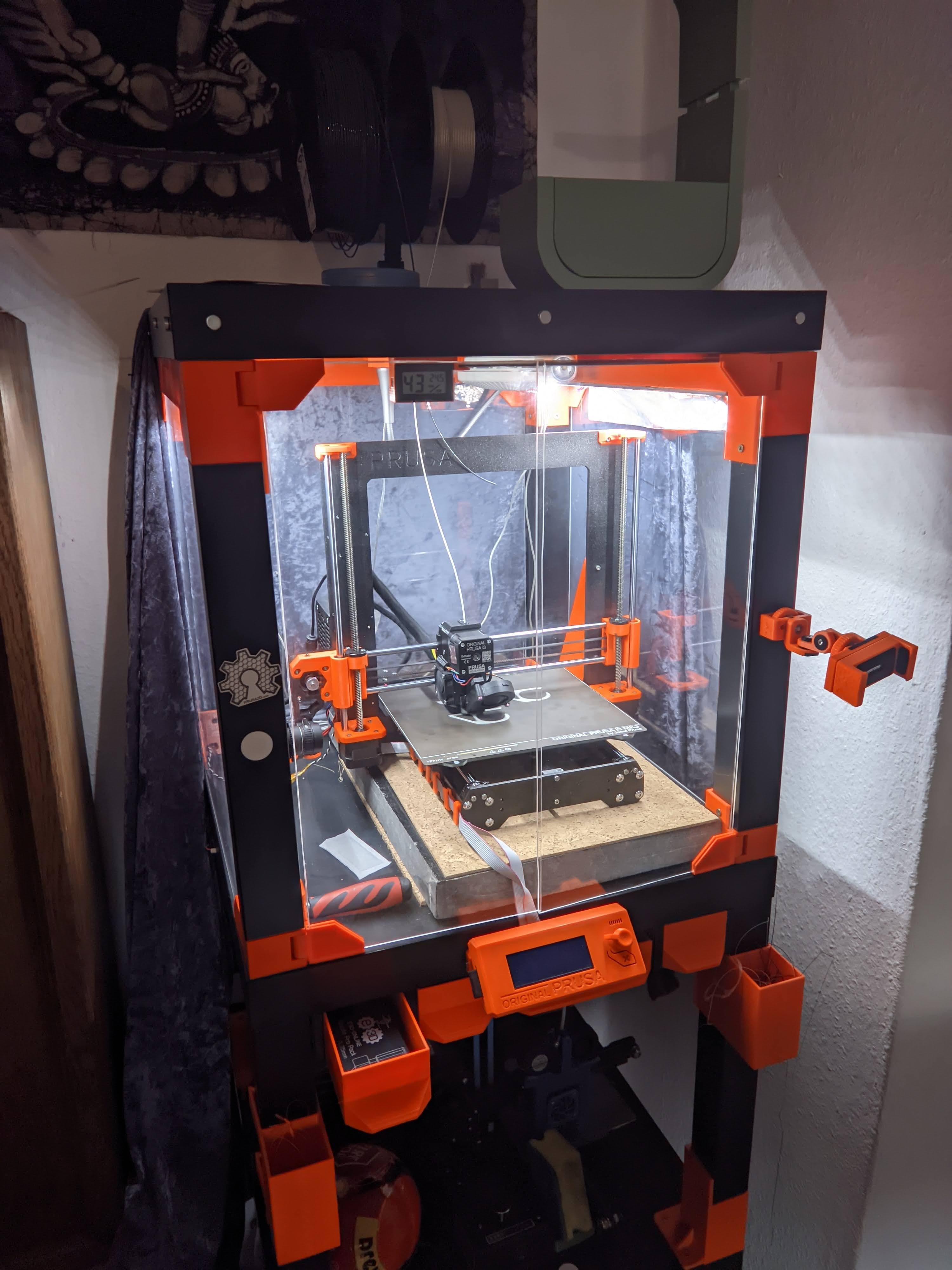

I started using a 3D Printer in early 2018, and by now I have two of them and they mostly do what I tell them to do. I built both of them from kits and heavily modified them. I control them via octoprint, a software that, with its open and helpful community, makes me proud to use it and taught me a lot about open-source principles. 3D Printing in the hobbyist space is a positive example where a method informs my design and I love all the areas it introduced me to. Through it, I felt more at home using Linux, programming, soldering, incorporating electronics, and iteratively designing. I love the abilities a 3D Printer gives me and plan on using it for the recycling project.

During the last half year, I also worked in a university context with 3D printers. We conceptualized and established a “Digitallabor”, an open space to enable all people to get into contact with innovative technologies. The idea was to create some form of Makerspace while emphasizing digital media. The project is young, it started in August last year and so most of my tasks were in Workgroups, deciding on the type of machines and types of content such a project can provide value with. Read more about it on the Website:

Looking forward, I am also incredibly interested in going beyond polymers for printing. I would love to be able to be more experimental concerning the material choices, something rather hard to achieve while staying in a shared student flat. There have been great projects with ceramics and printing, which I certainly want to have a deeper look into. One project I want to highlight is the evolving cups which impressed me a lot.

Evolving Objects This group from the Netherlands is algorithmically generating shapes of cups and then printing them on a paste extruder with clay. The process used is described more here:

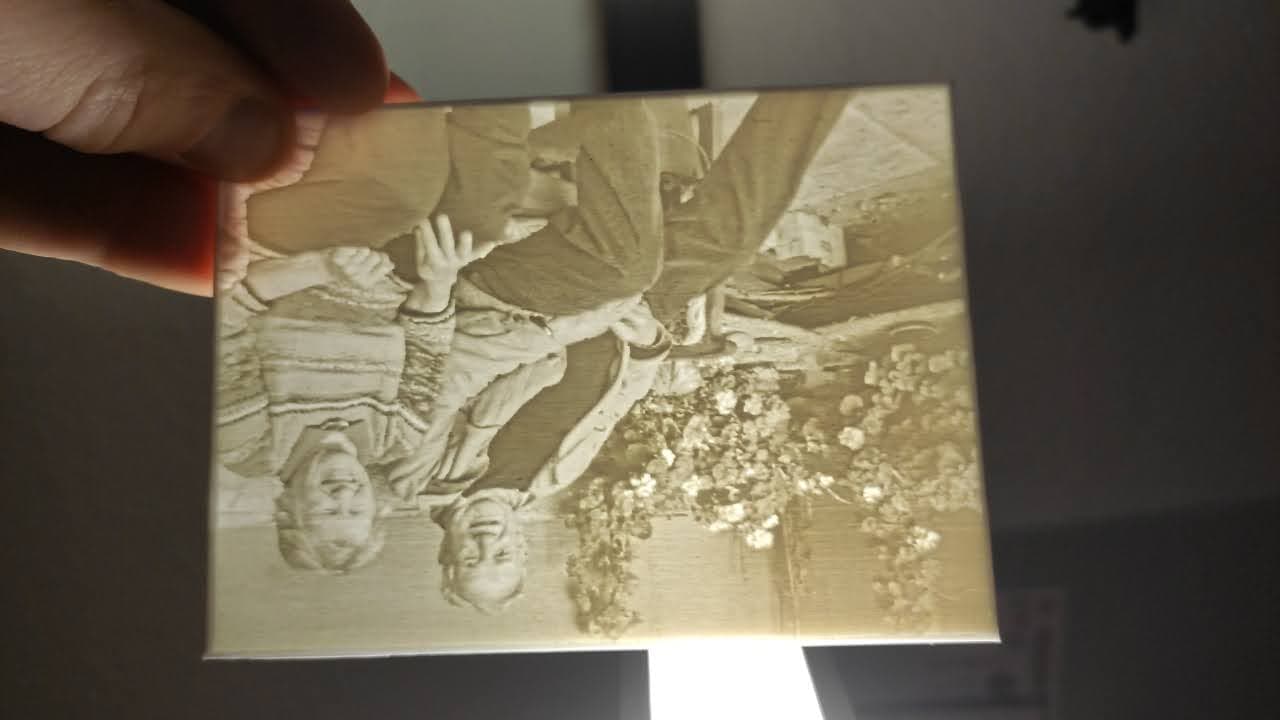

The artist Tom Dijkstra is developing a paste extruder that can be attached to modify a conventional Printer and I would very much love to develop my version and experiment with printing new and old materials in such a concept printer. Printing with Ceramics The Paste Extruder

Also with regards to the recycling project, it might make sense for me to incorporate multiple machines into one and let the printer itself directly handle pellet- or paste-form. I am looking forward to expanding my horizon there and seeing what is possible.

Cups and Tableware are of course just one sample area where a backtrack toward traditional materials within modern manufacturing could make sense. There is also more and more talk of 3D Printed Clay- or Earth homes, an area where WASP is a company I look up to. They built several concept buildings and structures from locally mixed earth, creating some awesome environmentally conscious structures.

Adhering to principles of local building with locally available materials and taking into account the infamous emission problem within the building industry has several great advantages. And since such alternative solutions are unlikely to come from the industry itself, one major avenue to explore and pursue these solutions are art projects and public demonstrations.

I want to explore all these areas and look at how manufacturing and sustainability can converge and create lasting solutions for society.

Also, 3D Printing is directly tied to the plans for my master’s thesis, since everything I manage to reclaim, will somehow have to end up being something again. Why not print away our waste?

Now, after a few years of tinkering, modifying and upgrading, I find that I did not change my current setup for over a year. It simply works and I am happy with it. Since my first beginner’s printer, the failure rates are negligible and I have had to print really complex parts in order to generate enough waste for the recycling project. Gradually, the mechanical system of the printer shifted from an object of care to simply a tool that I use. In the last years, hardware, but especially software has matured to a point where, at least to me, it tends to be a set-and-forget situation. On to actually making my parts and designs. Read more about that in the post about CAD